Key Takeaways

- Transmission repair costs range from $200 for minor fluid leaks to $6,500 for complete replacements

- Early warning signs include slipping gears, delayed shifting, fluid leaks, and burning smells

- Regular fluid changes every 30,000-60,000 miles can prevent most transmission failures

- Professional diagnosis is essential as modern transmissions contain complex computer-controlled systems

- Vehicles over 15 years old with high mileage may be better candidates for replacement rather than expensive repairs

Your vehicle’s transmission is a marvel of engineering that most drivers take for granted until something goes wrong. When transmission trouble strikes, the repair bills can be staggering, often ranging from hundreds to thousands of dollars depending on the severity of the problem. Understanding transmission repair isn’t just about saving money—it’s about making informed decisions that keep your car running smoothly and safely.

Modern automatic transmissions and manual transmissions have evolved into sophisticated systems that require specialized knowledge and equipment to diagnose and fix properly. Whether you’re dealing with minor transmission issues like fluid leaks or facing the prospect of a complete transmission rebuild, this comprehensive guide will help you navigate the complex world of transmission repairs.

From recognizing early warning signs to choosing between repair and replacement, we’ll cover everything you need to know about transmission maintenance services, costs, and professional automotive services. By the end of this guide, you’ll have the knowledge to make confident decisions about your car’s transmission and understand when it’s time to seek help from transmission experts.

Understanding Transmission Repair

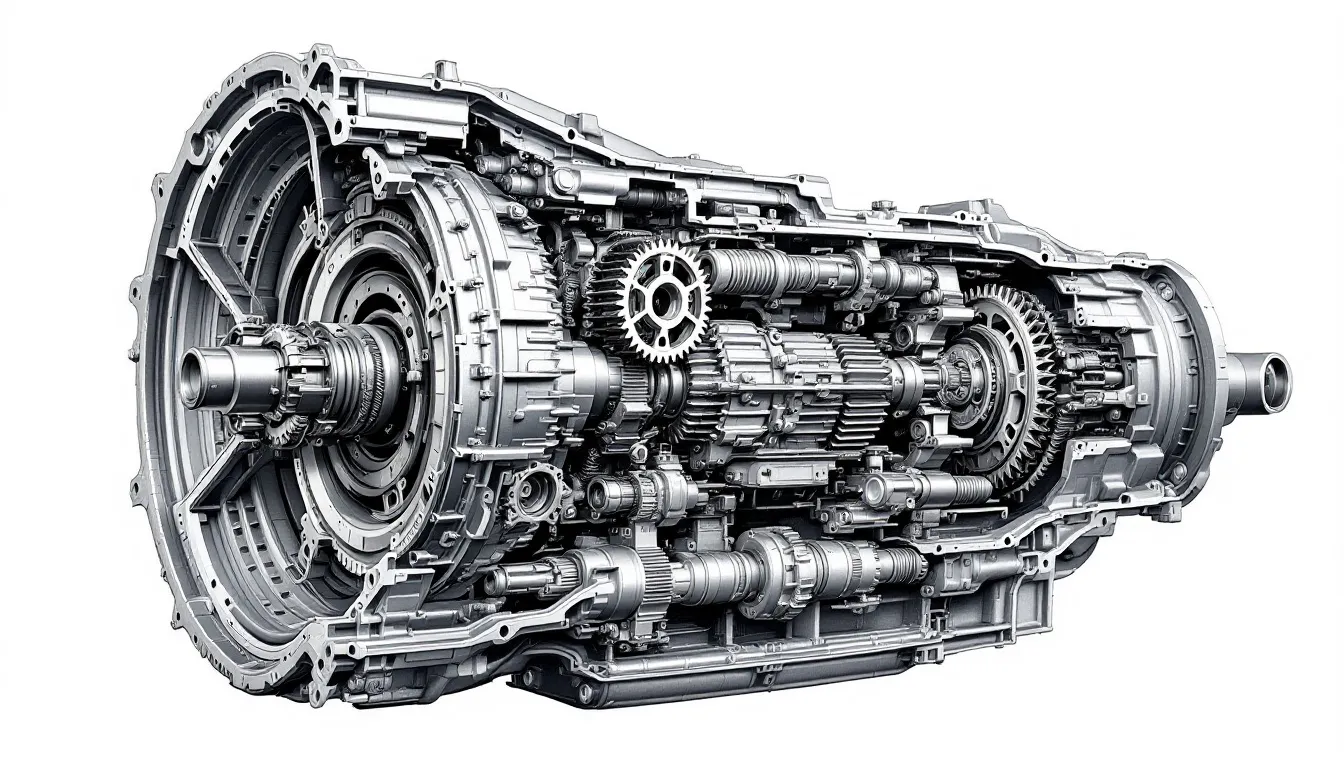

Transmission repair encompasses any work performed to restore the proper function of your vehicle’s transmission system. At its core, the transmission converts engine power into usable wheel rotation through a complex arrangement of gears, clutches, and hydraulic controls. When this system fails, it affects your car’s ability to move efficiently or at all.

The complexity of transmission repair varies significantly between automatic and manual transmissions. Manual transmissions, with their stick shift operation, contain fewer moving parts and rely on mechanical connections rather than computer controls. This simpler design makes many manual transmission repairs more straightforward and less costly than their automatic counterparts.

Automatic transmissions, however, represent some of the most sophisticated mechanical systems in modern vehicles. These transmissions use hydraulic pressure, electronic sensors, and computer controls to manage gear changes automatically. The rotational speed of various components must be precisely coordinated, requiring extensive diagnostic equipment to identify problems accurately. Modern automatic transmissions may contain dozens of solenoids, multiple speed sensors, and intricate valve bodies that control transmission fluid flow.

Transmission fluid serves as both a hydraulic medium and lubricant in automatic transmissions. This specialized fluid must maintain specific viscosity and chemical properties to ensure smooth operation. When transmission fluid becomes contaminated or drops to low fluid levels, it can cause immediate damage to internal components and trigger a cascade of failures throughout the transmission system.

Common Transmission Problems and Warning Signs

Recognizing the early signs of transmission trouble can save you thousands in repair costs. The most common symptom drivers experience is slipping gears, where the transmission unexpectedly changes gears or seems to lose power during acceleration. This often feels like the engine is revving but the car isn’t responding proportionally.

Delayed or rough shifting represents another critical warning sign, particularly the hesitation when moving from park to drive or reverse. Healthy transmissions should engage smoothly within one to two seconds. Extended delays or harsh engagement often indicate internal wear or hydraulic problems that require immediate attention.

Visual inspections can reveal important clues about your transmission’s condition. Red fluid leaks under your vehicle almost always indicate transmission fluid loss, which can quickly lead to catastrophic failure if not addressed. The location and size of these leaks help transmission experts determine the source and urgency of needed repairs.

A burning smell, especially when combined with dark or discolored transmission fluid, suggests overheating or severe internal damage. Fresh transmission fluid should appear bright red and have a slightly sweet odor. Brown or black fluid indicates contamination and oxidation that compromises the transmission’s ability to function properly.

The check engine light activation often relates to transmission sensors that monitor various system parameters. Modern vehicles use multiple sensors to track input and output shaft speeds, fluid temperature, and pressure levels. When these sensors detect abnormalities, they trigger warning lights and may put the transmission into a protective “limp mode” that limits performance to prevent further damage.

Grinding or whining noises during gear changes typically indicate mechanical wear in internal components. These sounds may be subtle at first but often become more pronounced as damage progresses. Professional diagnosis can determine whether the noise originates from worn clutch packs, damaged gears, or failing bearings.

Fluid-Related Issues

Transmission fluid condition provides valuable insight into your transmission’s internal health. Healthy fluid maintains a clear red color and flows smoothly when checked with the engine running and transmission warm. Contaminated fluid often appears brown or black and may contain visible metal particles that indicate internal component wear.

Low fluid levels create immediate problems for transmission operation. Insufficient fluid prevents proper hydraulic pressure buildup, causing delayed shifts, slipping, and potential component damage. Regular fluid level checks represent one of the most important aspects of routine maintenance that car owners can perform themselves.

Metal particles in transmission fluid serve as an early warning system for internal failures. Small amounts of metal debris are normal in high-mileage transmissions, but excessive particles or large chunks indicate significant component wear. Professional analysis of fluid samples can help determine the extent of internal damage and guide repair decisions.

Types of Transmission Repairs

Transmission repairs fall into several categories based on complexity and cost. Minor repairs typically address external issues like fluid leaks, filter replacement, or simple electrical problems. These repairs usually range from $200 to $800 and can often be completed within a day.

A basic transmission fluid exchange represents the most common maintenance service. This process involves draining old fluid from the transmission pan and refilling with new transmission fluid. Some shops also offer automatic transmission fluid exchange services that use specialized equipment to remove more old fluid than traditional drain-and-fill methods.

Filter replacement typically accompanies fluid changes, as the transmission filter removes contaminants from circulating fluid. A new pan gasket is usually installed during this service to prevent future leaks. This routine maintenance helps extend transmission life and maintain smooth operation.

Moderate repairs address internal component failures that don’t require complete teardown. Solenoid replacement represents a common moderate repair, as these electronic valves control fluid flow for gear changes. Modern transmissions may contain eight or more solenoids, each controlling specific functions. Individual solenoid replacement typically costs between $300 and $1,500 depending on accessibility and labor requirements.

Valve body repairs or replacements fall into the moderate category and can significantly improve transmission performance. The valve body serves as the transmission’s control center, directing hydraulic pressure to engage different gears. Rebuilding or replacing a damaged valve body requires specialized knowledge but costs less than complete transmission overhaul.

Major repairs involve significant internal work that requires transmission removal and teardown. Torque converter replacement addresses problems with the fluid coupling that connects the engine to the transmission. A failing torque converter can cause vibration, overheating, and poor fuel economy. Replacement typically costs between $1,500 and $4,000 including labor.

Complete transmission rebuild or replacement represents the most comprehensive repair option. Rebuilds involve completely disassembling the transmission, inspecting all components, and replacing worn or damaged parts. Quality rebuilds can restore like-new performance and often include updated components that address known design weaknesses. Costs typically range from $2,000 to $6,500 depending on the vehicle and shop quality.

Transmission Fluid Services

Professional transmission fluid services go beyond simple drain-and-fill procedures. A complete fluid flush uses specialized equipment to remove virtually all old fluid from the transmission system, including fluid trapped in the torque converter and cooler lines. This service typically replaces 100% of the fluid compared to 30-50% removed by conventional fluid changes.

The fluid exchange process often includes cleaning agents that help remove deposits and varnish buildup from internal components. Some shops combine the flush with a new filter installation and pan gasket replacement for comprehensive service. This thorough approach helps maximize the benefits of fresh transmission fluid.

Proper disposal of old transmission fluid is an important environmental consideration. Quality shops ensure used fluid is recycled properly and often participate in manufacturer take-back programs. The latest technology in fluid exchange equipment also minimizes waste and ensures consistent results across different vehicle types.

DIY vs Professional Transmission Repair

The complexity of modern transmissions limits realistic DIY repair options for most car owners. Basic maintenance tasks like checking fluid levels and identifying obvious leaks remain within reach of mechanically inclined drivers. However, internal transmission work requires specialized tools, knowledge, and clean working conditions that exceed most home garage capabilities.

DIY fluid changes are possible on vehicles with accessible transmission pans and drain plugs. This basic maintenance can help extend transmission life when performed correctly with the proper fluid type and quantity. Many manual transmissions have accessible drain and fill plugs that make fluid changes straightforward for experienced DIYers.

Filter replacement during DIY fluid changes requires careful attention to detail. The transmission pan must be removed, cleaned thoroughly, and reinstalled with a new pan gasket to prevent leaks. Proper torque specifications for pan bolts are critical, as over-tightening can warp the pan and cause persistent leaks.

Professional transmission repair becomes essential when dealing with internal problems or diagnostic challenges. Modern transmissions require computer scan tools to read fault codes and analyze sensor data. Professional diagnostic equipment can perform pressure tests, solenoid function checks, and other specialized procedures impossible without proper tools.

The risks of attempting complex DIY transmission repairs include voiding warranties, causing additional damage, and creating safety hazards. Transmission rebuilds require precise measurements, proper part selection, and extensive testing procedures. Mistakes during reassembly can result in immediate failure or premature wear that negates any cost savings.

Professional shops offer warranty coverage on parts and labor that protects customers from defective components or workmanship issues. This protection provides peace of mind and financial security that DIY repairs cannot match. Reputable shops also maintain relationships with parts suppliers and can source quality components at competitive prices.

Transmission Repair Costs Breakdown

Understanding transmission repair costs helps car owners budget for maintenance and make informed decisions about repair versus replacement. Diagnostic fees typically range from $100 to $200 and cover computer analysis, pressure testing, and visual inspection. Quality shops often apply diagnostic fees toward repair costs when customers authorize recommended work.

Basic transmission fluid service costs vary based on fluid capacity and vehicle complexity. Simple drain-and-fill services typically cost $150 to $250, while complete flush services range from $200 to $400. Vehicles requiring synthetic transmission fluid or specialty formulations may cost more due to higher fluid prices.

Seal and gasket repairs address external leaks that can lead to catastrophic failure if ignored. Pan gasket replacement typically costs $200 to $400 including fluid, while more complex seal repairs may reach $600 depending on accessibility. Output shaft seals, input shaft seals, and pump seals require varying levels of transmission disassembly.

Solenoid replacement costs depend on the specific solenoid location and transmission design. External solenoids accessible without transmission removal may cost $300 to $500 including labor. Internal solenoids requiring partial teardown can cost $500 to $700 per unit. Some modern transmissions use integrated solenoid blocks that must be replaced as complete assemblies.

Major repair costs reflect the extensive labor and parts required for internal work. Transmission rebuilds typically range from $1,800 to $4,500 for domestic vehicles and $2,500 to $5,500 for imports. These costs include complete teardown, inspection, parts replacement, reassembly, and testing. Quality rebuilds often include updated components that improve reliability over original designs.

Labor costs represent a significant portion of transmission repair expenses. Specialized transmission shops typically charge $100 to $150 per hour for expert technicians. Complex repairs may require 15 to 25 hours of labor for complete rebuilds. Removal and installation procedures vary significantly between vehicle models, affecting total labor time and cost.

When to Repair vs Replace Your Transmission

The decision between repairing and replacing a transmission depends on several economic and practical factors. Vehicle age and mileage provide important context for repair decisions. Vehicles with over 200,000 miles may not justify expensive transmission rebuilds, especially if other major components show signs of wear.

Cost comparison using current vehicle values helps determine economic feasibility of major repairs. Kelley Blue Book or similar valuation services provide baseline values for repair decision making. Generally, transmission repairs exceeding 50% of vehicle value warrant serious consideration of replacement options.

Frequency of previous transmission problems indicates whether current issues represent isolated failures or systematic wear. Vehicles with multiple previous transmission repairs may benefit from complete replacement rather than continued spot repairs. Pattern failures often indicate that underlying design issues or contamination problems will continue causing problems.

Overall vehicle condition affects repair justification beyond simple cost calculations. Well-maintained vehicles with recent investment in other systems may warrant transmission rebuilds to extend overall life. Conversely, vehicles with multiple deferred maintenance issues may not justify major transmission investment.

Availability of replacement parts influences repair feasibility for older or discontinued models. Some vintage vehicles require custom fabrication or remanufacturing of unavailable components. These specialty requirements can make repairs extremely expensive compared to more common vehicles.

Rebuild vs Replacement Options

Remanufactured transmissions offer factory-quality rebuilds with updated components and comprehensive warranties. These units often include design improvements that address known weaknesses in original transmissions. Remanufactured units typically cost 40-60% less than new transmissions while providing similar reliability and warranty coverage.

Rebuilt transmissions using existing cases with new internal parts represent a middle-ground option. Quality rebuilds can provide excellent reliability when performed by experienced shops using quality components. The existing case and external components are retained while internal wear items are replaced with new or remanufactured parts.

Used transmissions from salvage yards provide the lowest-cost replacement option but carry significant risks. Warranty coverage on used transmissions is typically limited to 30-90 days, and the history of the used unit is often unknown. Mileage verification and previous maintenance records are rarely available for salvage yard transmissions.

New OEM transmissions represent the premium replacement option for newer vehicles still under manufacturer support. These transmissions include the latest design updates and full warranty coverage but command premium prices. New transmissions are typically justified only for newer vehicles or specialty applications where maximum reliability is essential.

Choosing the Right Transmission Repair Shop

Selecting a qualified transmission repair shop requires careful evaluation of credentials, capabilities, and reputation. ASE (Automotive Service Excellence) certification indicates technicians have demonstrated competency in transmission repair through standardized testing. Additional manufacturer training credentials show commitment to staying current with evolving transmission technology.

Warranty offerings provide insight into shop confidence and quality standards. Reputable shops offer minimum 12-month warranties on major repairs, with premium shops providing 24 to 36-month coverage. Warranty terms should cover both parts and labor, and shops should clearly explain what conditions might void warranty coverage.

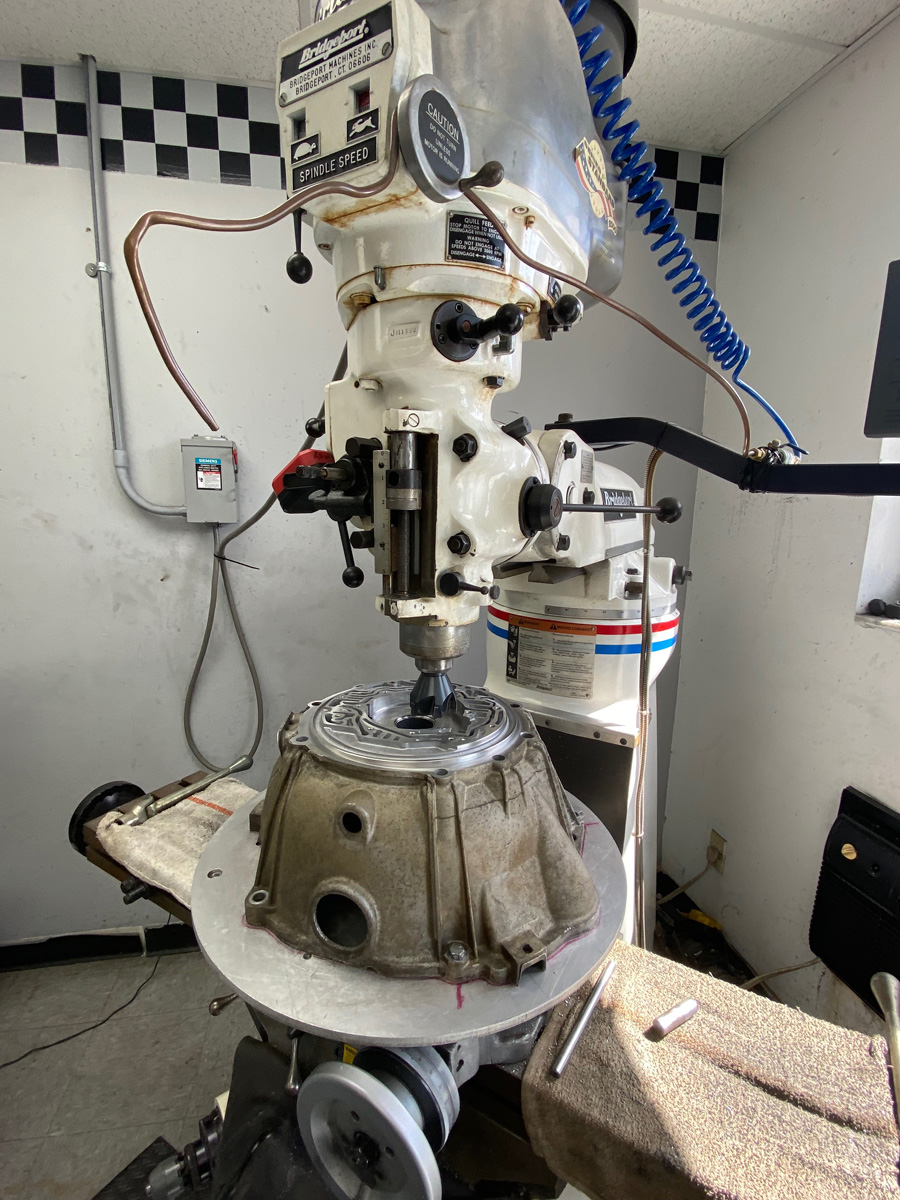

Diagnostic capabilities separate professional transmission shops from general repair facilities. Modern transmission diagnosis requires specialized computer scan tools, pressure testing equipment, and oscilloscopes for electrical analysis. Shops lacking proper diagnostic equipment cannot accurately identify problems or verify repair success.

Customer reviews and Better Business Bureau ratings provide valuable insight into shop reliability and customer satisfaction. Online review platforms often reveal patterns of customer experiences that indicate shop strengths and weaknesses. BBB accreditation and complaint resolution history demonstrate commitment to customer service and ethical business practices.

Specialization in transmission work indicates focused expertise compared to general automotive repair shops. Dedicated transmission shops maintain specialized tools, parts inventory, and technical knowledge that general shops cannot match. These shops often have relationships with remanufacturing companies and access to updated component designs.

Facility tours can reveal important information about shop capabilities and quality standards. Clean, organized shops with modern equipment typically indicate professional operations. Shops willing to explain their processes and show their work areas demonstrate confidence in their capabilities and transparency in their operations.

Preventive Maintenance to Avoid Transmission Repair

Regular preventive maintenance represents the most cost-effective approach to transmission longevity. Simple fluid level checks with the engine running and transmission warm can identify developing problems before they cause major damage. Most vehicles provide dipstick access for owner monitoring, though some newer models require professional equipment for accurate readings.

Following manufacturer service intervals for transmission fluid changes typically ranges from 30,000 to 60,000 miles depending on driving conditions and transmission type. Severe service conditions like frequent towing, stop-and-go traffic, or extreme temperatures may require more frequent service. Maintaining service records helps demonstrate proper care and may preserve warranty coverage.

Driving habits significantly impact transmission longevity and repair frequency. Aggressive acceleration, hard braking, and rapid temperature changes stress transmission components beyond normal design limits. Allowing the engine and transmission to warm up before heavy acceleration helps ensure proper fluid viscosity and component lubrication.

Proper towing procedures and weight limits prevent transmission overheating and premature wear. Exceeding manufacturer towing capacities or failing to use transmission coolers when required can cause catastrophic failure. Even occasional overloading can damage clutch packs and bands that are expensive to replace.

Addressing small leaks and minor issues prevents them from becoming major problems requiring extensive repairs. Small fluid leaks can quickly become major problems if ignored, as low fluid levels cause rapid component damage. Early intervention for minor problems like seal leaks or sensor failures costs far less than waiting for complete system failure.

Regular inspection of transmission cooler lines, mounts, and external components helps identify potential problems before they cause damage. Transmission mounts that allow excessive movement can stress internal components and cause premature wear. Damaged cooler lines can cause fluid loss and overheating that destroys internal components quickly.

Atlas Transmission: Your Trusted Transmission Repair Partner

Atlas Transmission brings over 25 years of specialized transmission repair experience to drivers throughout the local community. Our commitment to excellence has made us the preferred choice for customers seeking reliable transmission services and honest automotive advice. We understand that transmission problems can be stressful and expensive, which is why we focus on clear communication and quality workmanship for every customer.

Atlas Transmission brings over 25 years of specialized transmission repair experience to drivers throughout the local community. Our commitment to excellence has made us the preferred choice for customers seeking reliable transmission services and honest automotive advice. We understand that transmission problems can be stressful and expensive, which is why we focus on clear communication and quality workmanship for every customer.

Our team of ASE-certified technicians receives ongoing training on both domestic and import transmissions to stay current with evolving automotive technology. This expertise allows us to work confidently on everything from classic muscle cars with stick shift transmissions to the latest vehicles with complex computer-controlled automatic transmissions. We maintain the specialized tools and diagnostic equipment necessary to accurately identify problems and verify repair quality.

State-of-the-art diagnostic equipment sets Atlas Transmission apart from general automotive shops. Our computerized testing systems can analyze transmission performance, identify failing components, and verify proper operation after repairs. This technology-driven approach ensures accurate problem identification and eliminates guesswork that can lead to unnecessary repairs or comeback issues.

We stand behind our work with comprehensive warranties covering parts and labor for up to 3 years, depending on the service performed. Our warranty coverage reflects our confidence in using quality components and performing meticulous work. We clearly explain warranty terms and maintain detailed service records to ensure our customers receive full protection for their investment.

Atlas Transmission provides free initial diagnosis and detailed estimates before beginning any work. We believe customers deserve to understand their options and make informed decisions about their vehicle repairs. Our estimates include clear explanations of recommended work, alternative options, and honest assessments of repair versus replacement decisions.

Our service capabilities include both automatic and manual transmission repair, rebuilds, and replacement services. We maintain extensive parts inventory for common repairs and have established relationships with remanufacturing companies for quality replacement units. Whether you need routine maintenance like an automatic transmission fluid exchange or major repairs, we have the expertise and equipment to service your vehicle properly.

Competitive pricing combined with flexible payment options and financing availability makes quality transmission service accessible to more customers. We work with several financing partners to offer qualified customers extended payment terms for major repairs. Our transparent pricing includes detailed breakdowns of parts and labor costs without hidden fees or surprise charges.

Understanding that transmission failures can leave customers stranded, Atlas Transmission provides 24-hour towing service for vehicles that cannot be driven safely. Our towing partners are experienced with transmission-related breakdowns and can safely transport your vehicle to our facility for diagnosis and repair. This service ensures you’re not left stranded when transmission trouble strikes unexpectedly.

Frequently Asked Questions

How long does a typical transmission repair take?

The duration of transmission repairs varies significantly based on the complexity of the work required. Minor repairs like fluid changes or filter replacements typically take 1-2 hours and can often be completed while you wait. Moderate repairs such as solenoid replacements may require 4-8 hours depending on accessibility and vehicle design.

Major repairs like transmission rebuilds require 2-5 business days depending on parts availability and shop workload. Complete rebuilds involve extensive teardown, inspection, parts ordering, reassembly, and testing procedures that cannot be rushed. Emergency repairs may receive priority scheduling, but quality work requires adequate time for proper procedures and testing.

Can I drive with transmission problems?

Driving with transmission issues can cause additional damage and safety risks that far exceed the cost of immediate professional attention. Minor symptoms like slight hesitation during shifts may allow short-distance driving to reach a repair facility, but continuing normal operation often worsens the damage significantly.

Complete loss of gears, severe slipping, or fluid leaks require immediate towing to prevent catastrophic failure. Attempting to drive with major transmission problems can damage other vehicle systems and create dangerous situations where the vehicle loses power unexpectedly. When in doubt, contact a professional for advice rather than risking further damage.

What’s the difference between a transmission flush and fluid change?

A conventional fluid change involves draining the transmission pan and replacing 30-50% of the total fluid capacity. This service typically includes filter replacement and pan gasket installation but leaves a significant amount of old fluid in the torque converter and cooler lines.

A transmission flush uses specialized equipment to remove nearly 100% of old fluid from the entire system. The flush process includes cleaning agents that help remove deposits and varnish buildup from internal components. While more thorough, flushes are not always recommended for high-mileage transmissions where disturbing settled deposits might cause problems.

How can I tell if my transmission needs a rebuild or just repair?

Professional diagnosis with pressure tests and computer scans determines the extent of internal damage and helps guide repair decisions. Multiple problems, metal contamination in fluid, or widespread component wear typically indicate that a rebuild is more cost-effective than repeated spot repairs.

Single-component failures in otherwise healthy transmissions may justify targeted repairs, especially in newer vehicles. However, transmission components often wear together, so addressing only the failed part may provide only temporary relief. A qualified technician can assess the overall condition and recommend the most appropriate approach based on your vehicle’s specific situation.

Are remanufactured transmissions as good as new ones?

Quality remanufactured transmissions often include updated components that improve on original designs and address known weak points. These units undergo complete teardown, inspection, and reassembly with new or rebuilt components that meet or exceed original specifications. Reputable remanufacturers provide warranties similar to new units at 40-60% less cost.

The key to remanufactured transmission quality lies in the remanufacturer’s reputation and processes. Established companies with proven track records typically provide reliable units with comprehensive warranty coverage. However, cheaper remanufactured options may use substandard components or inadequate quality control that reduces reliability and longevity.